Design, Verification by FEA and Simulations, Optimisation

ProSIM has competence in conducting advanced finite element analysis (FEA) & multi-physics simulations, and deriving the useful engineering insights from the simulations for further decision making by the designers. We analyse results of FEA and simulations to provide engineering solutions to complex problems by our insights and engineering judgement expertise. Such post processing of FEA results lead to

- Design Optimisation (Sizing /shape/ topology/ parametric optimisations)

- Seismic evaluation & Qualification (as per industry standard codes / standards)

- Structural integrity assessment

- Remaining life assessment & extension (RLA/RLE), fitness for service (FFS) etc.

- Component / system life assessment (fatigue life)

- Failure analysis

- Localistaion and indegenisation

Computer Aided Engineering (CAE) Services

ProSIM is a computer aided engineering service provider. Computer aided engineering outsourcing is a key offering of ProSIM.

CAE services from ProSIM include CAE offshore service, CAE onsite consulting, CAE outsourcing. As part of its engineering outsourcing and engineering design service offering,

As part of its onsite CAE placement service offering, ProSIM places its engineers at customers’ sites as computer aided engineering consultants (CAE consultants). To make this system of high value to customers, ProSIM custom trains engineers in CAE tools (such as Hypermesh). ProSIM provides Hypermesh CAE service, Hypermesh onsite placement service, and also hypermesh outsourcing service including hypermesh offshore service for overseas customers. ProSIM has master service agreements with several global majors for onsite CAE placement /onsite CAE service.

ProSIM is a company with high levels of skills and expertise in CAE processes. ProSIM provides computer aided engineering (CAE) services to companies in India and overseas. Outsourced/ off shored CAE services include meshing (in commercial software such as Hypermesh), assigning material and boundary conditions, preprocessing and deck setting for analysis in various simulation and FEA software such as ANSYS, Abaqus, Nastran, etc. As members of premier computer aided engineering (CAE) outsourcing services company, ProSIM engineers have been trained to understand the importance of quality control of FE/ CFD mesh, depending on the type of analysis needed; to control the element size and mesh density, and provide the mesh decks of required quality to customers.

ProSIM engineers have been deployed onsite at our customer premises as computer aided engineering (CAE) consultants.

ProSIM has been working as partner to many companies for computer aided engineering outsourcing, and executing CAE projects at its facilities in Bangalore, India.

Finite Element Analysis (FEA Services)

ProSIM is a leading finite element analysis consultancy service (FEA consultancyservices) company providing multi-physics simulation based design verification and design optimization services.

We use opensource FEA software and commercial software for code check and qualification in conjunction with various industry standard codes (such as ASME B&PV, API, EN, ISO, IEEE, DNVGL, etc) to provide engineering design services,off-shore FEA service.

We place our engineers at our customer locations as FEA consultants. This includes ANSYS onsite placement, Optistruct onsite placement, Radioss onsite placement and so on.

ProSIM is a leading finite element analysis outsourcing companyproviding ANSYS FEA service outsourcing, optistruct FEA service outsourcing, Radioss FEA service. We custom train our engineers to carryout specific jobs of our customers for Ansys finite element service or Ansys finite element analysis service outsourcing; or Optistruct finite element analysis service or Radioss finite element analysis service.

Finite element analysis services from ProSIM include deploying ProSIM engineers as FEA engineering consultantsfor Ansys onsite placement service. As a part of FEA engineering consultancyProSIM custom trains its engineers in products and technologies and in FEA software usage eg, for Ansys onsite placement service.

FEA engineering service of ProSIM includes FEA outsourcing service, FEA onsite placement service, offshoreOptistruct FEA service. FEA services to Bangalore, India.

Design verification by FEA is a core capability of ProSIM. At ProSIM we use finite element analysis to determine the design sufficiency under operating conditions of the component/ system/ equipment. We verify the adequacy of factor of safety checking the allowable stress. We use finite element analysis results to determine the strength and stiffness.

ProSIM is an expert FEA consultancy services group in Bangalore, India. Finite element analysis (FEA) is a core competency of ProSIM. Using their skills in using variety of commercial /open source software (such as ANSYS, Optistrcut, Radioss, Abaqus, Nastran, Code Aster Etc), ProSIM FEA engineering services include all types of finite element analysis including time domain and frequency domain analysis. Finite element analysis services from ProSIM include all types of complex and high end FEA.

Linear Static Analysis

Dynamic Analysis (Modal, Harmonic, transient dynamics0

Time series analysis, frequency response analysis, response spectra analysis,

Non-linear analysis ( non-linear materials, contacts, and geometric nonlinearity)

Response spectra analysis

Structural analysis

Coupled thermo-mechanical analysis

ProSIM engineers work at customer locations onsite or in ProSIM premises as FEA engineering consultants. As FEA consultants ProSIM engineers perform variety of jobs including creating FE models, executing finite element analysis models, post processing of results, doing quality checks, deriving engineering insights out of FE analysis results, generating reports, etc. Quite often ProSIM engineers also interface with end users/ end customers. Due to these value adds ProSIM has become a preferred company fore finite element analysis (FEA) outsourcing services. ProSIM has offered finite element analysis consultancy services to several industrial sectors including:

Nuclear Power

Energy (including thermal power, oil and gas, off-shore, wind, nuclear,

Automotive

Aerospace and defence

Electrical and Electronics

CFD & Multi-physics simulation services

In addition to CAE/ FEA services, ProSIM has been providing Multi physics simulation based services and engineering solutions to customers. These services include.

Multi-body dynamics (MBD)

Materials constitutive and damage modeling (using finite element analysis); Fatigue, Creep, creep-fatigue interaction, crack growth simulations

Coupled electro-magnetic-thermal-structural-flow analysis

Computational fluid dynamics (CFD), including fluid structure interactions, multi-phase flow

Design Verification and Design Optimisation services.

ProSIM assists customers to optimsie their products / components/ equipment/ systems. We are well versed with sizing optimization, topology optimization and parametric optimization.

ProSIM offers CAE, FEA, and multi-physics simulation based services in flexible business models to customers.

Outsourced / Off-shored CAE, FEA services executed by ProSIM team at ProSIM Bangalore India.

Onsite consulting services at customer locations globally.

Hybrid models combining benefits of onsite+ outsourced models to give maximum flexibility and benefits to customers.

Creation of joint development teams to accomplish specific missions of our customers.

Towards this we have

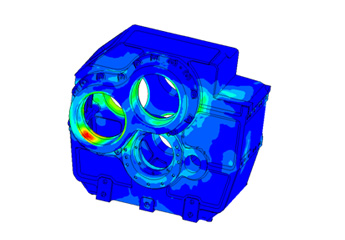

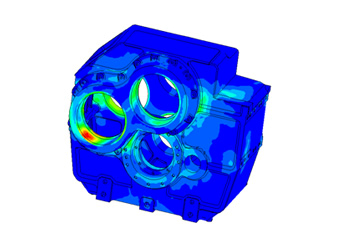

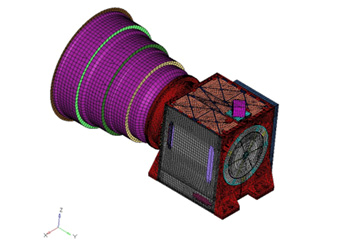

Optimisation of gear box of fast attack craft (FAC).

Gear box designed had excess weight. ProSIM has conducted multi-body dynamic analysis to determine the dynamic forces induced on the gear box housing bearing locations, carried out dynamic stress analysis using finite element analysis (FEA), determined the fatigue life (durability). Using parametric optimization techniques, ProSIM optimized the number, size, and shape of ribs, thickness of housings, and obtained the needed weight reduction without compromising on the performance conditions of deflections, vibration, noise, and fatigue life. ProSIM provided FEA consultancy services that helped customer get his product approved by the end user.

Structural Integrity and Thermal Management Assessment of Sensors used in Spacecraft

ProSIM has worked on several sensors for variety of space applications including missions of Chandrayan and Mangalayan. Sensors are virtually tested for extreme conditions using finite element analysis based simulations. Modal analysis, quasistatic stress analysis, random vibration analysis, sine, bump, shock analysis, thermal analysis including conduction and radiation heat transfer, thermal shock analysis, were conducted using appropriate FEA models. ProSIM has worked as partners with ISRO for FEA outsourcing consultants.

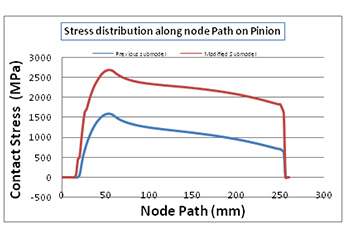

Contact Stress and Contact Area Calculations in Mating Gear Pairs

Accurate contact stresses computation is very important to determine the contact area, which in turn will determine the noise, wear, fatigue, life, etc.

ProSIM has expertise to calculate the contact stresses accurately using non-linear finite element analysis (FEA) by adopting accurate sub-modeling procedures. Figure shows the contact stress graphs. The graph of contact stress shows disparity in contact stress calculation if an appropriate sub modeling procedure is not used. ProSIM assisted customer to design the gear box for longer life and lower noise. ProSIM engineers worked as finite element analysis consultants and solved this critical problem to customer.

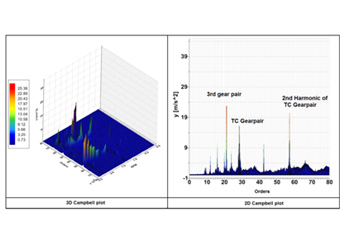

Vibration Order Analysis – Campbell diagram of gear box

Gear box vibrations are analysed using FEA and multibody dynamic simulations. 2D and 3D Campbell diagrams are plotted. Critical RPM for gear pair that causes high vibrations is identified. Interpreting the results of FEA, and MBD simulations, cause of high vibration (and noise) was analysed and eliminated.

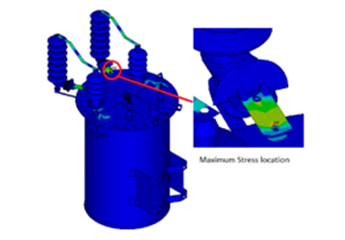

Coupled Electro-magnetic-thermal-structural analysis of transformers

ProSIM has worked with many transformer companies to predict stray losses, temperature rise, effect of cooling media, thermo-mechanical stress generation, vibrations to optimize the thermal and mechanical structures using FEA. ProSIM has also used finite element analysis to study the transportation load cases including road, rail, ship, and aircraft as per codes of practice in various geographies. Provides finite element analysis and Multiphysics simulation based design verification and design optimization services to electrical machinery companies involved in making motors and drives, generators, alternators, transformers, sensors etc.