Design, Verification by FEA and Simulations, Optimisation

Core competence of ProSIM is in conducting advanced finite element analysis (FEA) & multi-physics simulations, and deriving the useful engineering insights from the simulations for further decision making by the designers.We post process the results of FEA and simulations to provide engineering solutions to complex problems by our insights and engineering judgement expertise. Such post processing of FEA results lead to

- Design Optimisation (Sizing /shape/ topology/ parametric optimisations)

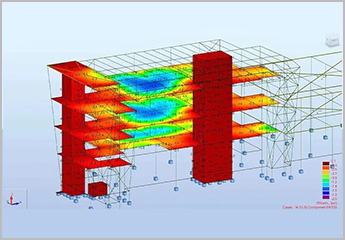

- Seismic evaluation & Qualification

- Structural integrity assessment

- (remaining life assessment & extension (RLA/RLE), fitness for service (FFS) etc.)

- Component / system life assessment (fatigue life)

- Failure analysis

- Localistaion and indegenisation

ProSIM offers CAE,FEA, and multi-physics simulation based services in flexible business models to customers.

- Outsourced / Off-shored CAE, FEA services executed by ProSIM team at ProSIM Bangalore India.

- Onsite consulting services at customer locations globally.

- Hybrid models combining benefits of onsite+ outsourced models to give maximum flexibilityand benefits to customers.

- Creation of joint development teams to accomplish specific missions of our customers.

- Towards this we have

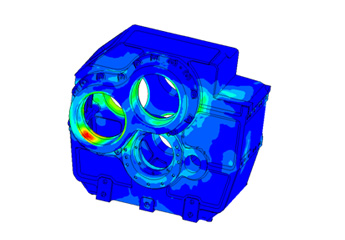

Optimisation of gear box of fast attack craft (FAC).

Gear box designed had excess weight. ProSIM has conducted multi-body dynamic analysis to determine the dynamic forces induced on the gear box housing bearing locations, carried out dynamic stress analysis using finite element analysis (FEA), determined the fatigue life (durability). Using parametric optimization techniques, ProSIM optimized the number, size, and shape of ribs, thickness of housings, and obtained the needed weight reduction without compromising on the performance conditions of deflections, vibration, noise,and fatigue life.

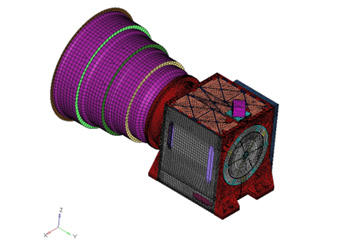

Structural Integrity and Thermal Management Assessment of Sensors used in Spacecraft

ProSIM has worked on several sensors for variety of space applications including missions of Chandrayan and Mangalayan. Sensors are virtual tested for extreme conditions using finite element analysis based simulations. Modal analysis, quasistatic stress analysis, random vibration analysis, sine, bump, shock analysis, thermal analysis including conduction and radiation heat transfer, thermal shock analysis, were conducted using appropriate FEA models.

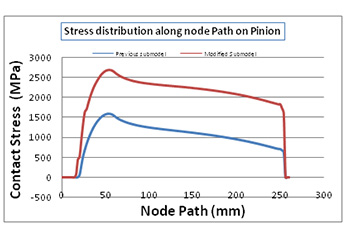

Contact Stress and Contact Area Calculations in Mating Gear Pairs

Accurate contact stresses computation is very important to determine the contact area, which in turn will determine the contact area, noise, fatigue life, etc.

ProSIM has expertise to calculate the contact stresses accurately using non-linear finite element analysis (FEA) by adopting correct sub-modeling procedures. Figure shows the contact area and stress contours. The graph of contact stress shows disparity in contact stress calculation for an accurate method of FEA analysis and a non-pricise FEA model used earlier by the customer. ProSIM assisted customer to design the gear box for longer life and lower noise.

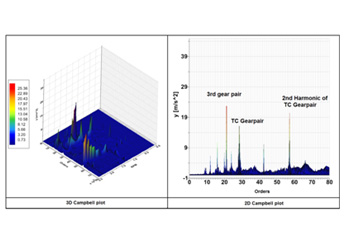

Vibration Order Analysis – Campbell diagram of gear box

Gear box vibrations are analysed using simulations. 2D and 3D Campbell diagrams are plotted. Critical RPM for gear pair that causes high vibrations is identified.

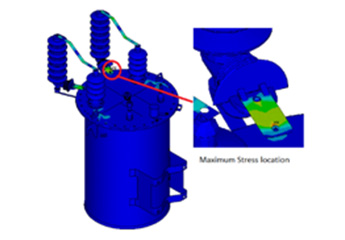

Coupled Electro-magnetic-thermal-structural analysis of transformers

ProSIM has worked with many transformer companies to predict stray losses, temperature rise, effect of cooling media, thermo-mechanical stress generation, vibrations to optimize the thermal and mechanical structures using FEA. ProSIM has also used finite element analysis to study the transportation load cases including road, rail, ship, and aircraft as per codes of practice in various geographies.